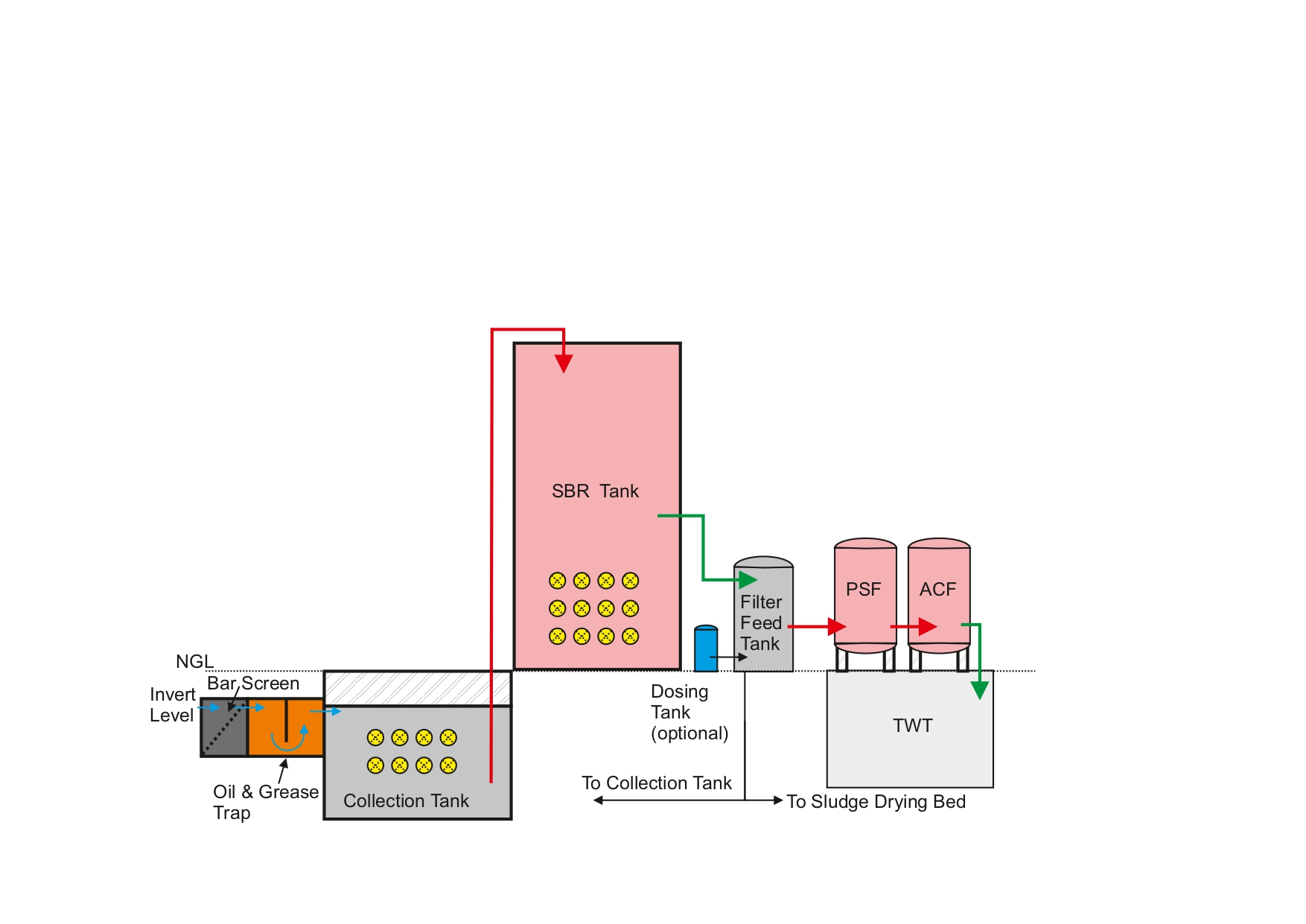

SBR TECHNOLOGY :

The Sequential Batch Reactor ( SBR) is an activated sludge process designed to operate on a “ 1 batch at a time” . SBR operates in a true batch mode with aeration & sludge settlement occurring in same tank. The no. of batches depends upon the quality & qty. of sewage to be treated in a day.

Various steps of SBR Process is as :

Stage 1 : The influent waste water is distributed throughout the settled sludge to provide good contact between substrate & the microorganisms . Most of this period occurs without aeration to create an environment that favors procreation of microorganisms with good settling characteristics. Aeration starts at the beginning of this period.

Stage 2 :Mixed Liquor is mixed with the influent flow. During this period microorganisms are in contact with the substrate & a large amount of Oxygen is provided to facilitate substrate consumption..

Stage 3 :The sewage is pumped into SBR tank, which acts as a biological selector enhancing the growth of bacteria ,where BOD removal occurs. Aeration continues till complete biodegradation of BOD is achieved. After

the substrate is consumed famine stage starts. During this stage some micro organisms will die because of lack of food & will help reduce volume of settling sludge. Timing for aeration & resultant sludge determines the treatment level. Timing of aeration depends on the quality of waste water .

After aeration phase, sludge separation occurs in the settling phase. During this period aeration is discontinued & solids separation starts taking place leaving clear treated effluent above the sludge blanket. During this period it is ensured that no liquid should either enter or leave the tank to avoid turbulence in the supernatant. Period of settling may vary from cycle to cycle depending on quality of sewage & no. of batches.

Stage 4 : After settling, the clear water from top is removed without agitating sludge . During decantation, water is drawn below the surface leading to low suspended solids.

The treated water is disinfected by using chlorine and filtered through PSF & ACF which act as polishing agents to produce crystal clear water prior to reuse for gardening and toilet flushing.

Stage 5 : The reactor tank rests in idle condition till next batch is taken for treatment